Rocket engine nozzles

Encyclopedia

Propelling nozzle

A propelling nozzle is the component of a jet engine that operates to constrict the flow, to form an exhaust jet and to maximise the velocity of propelling gases from the engine....

(usually of the de Laval

De Laval nozzle

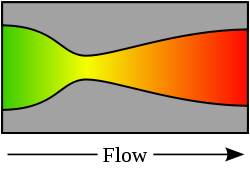

A de Laval nozzle is a tube that is pinched in the middle, making a carefully balanced, asymmetric hourglass-shape...

type) used in a rocket engine

Rocket engine

A rocket engine, or simply "rocket", is a jet engineRocket Propulsion Elements; 7th edition- chapter 1 that uses only propellant mass for forming its high speed propulsive jet. Rocket engines are reaction engines and obtain thrust in accordance with Newton's third law...

to expand and accelerate the combustion

Combustion

Combustion or burning is the sequence of exothermic chemical reactions between a fuel and an oxidant accompanied by the production of heat and conversion of chemical species. The release of heat can result in the production of light in the form of either glowing or a flame...

gases produced by burning propellants so that the exhaust gases exit the nozzle at hypersonic

Hypersonic

In aerodynamics, a hypersonic speed is one that is highly supersonic. Since the 1970s, the term has generally been assumed to refer to speeds of Mach 5 and above...

velocities.

History

The de Laval nozzle was originally developed in the 19th century by Gustaf de LavalGustaf de Laval

Karl Gustaf Patrik de Laval was a Swedish engineer and inventor who made important contributions to the design of steam turbines and dairy machinery.-Life:De Laval was born at Orsa in Dalarna...

for use in steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

s. It was first used in an early rocket engine developed by Robert Goddard, one of the fathers of modern rocketry. Subsequently, almost all rocket engines used this idea, including Walter Thiel

Walter Thiel

Dr Walter Thiel was a German rocket scientist.He was the third civilian hired by Walter Dornberger for German research at Kummersdorf on November 1, 1932, , and in 1936, transferred to Dornberger's new rocket section...

's implementation which made possible Germany's V2 rocket.

Atmospheric use

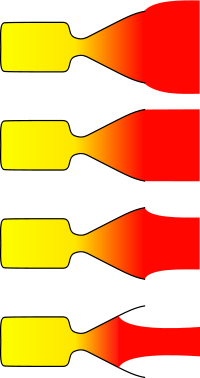

The optimal size of a rocket engine nozzle to be used within the atmosphere is when the exit pressure equals ambient pressure, which decreases with altitude. For rockets travelling from the Earth to orbit, a simple nozzle design is only optimal at one altitude, losing efficiency and wasting fuel at other altitudes.If the pressure of the jet leaving the nozzle is above ambient pressure then a nozzle is said to be 'underexpanded'; if the jet is below ambient pressure then it is 'overexpanded'.

Slight overexpansion causes a slight reduction in efficiency, but otherwise does little harm. However, if the jet pressure is approximately 40 percent of ambient then 'flow separation' occurs. This can cause jet instabilities that can cause damage to the nozzle or simply cause control difficulties of the vehicle or the engine.

In some cases it is desirable for reliability and safety reasons to ignite a rocket engine on the ground that will be used all the way to orbit. For optimal liftoff

Liftoff

-Plot:Having just been promoted, it's CJ's first day as Chief of Staff. After being introduced to the Secret Service Agents assigned to protect her, it is time for her last press briefing, where she receives a huge round of applause from a stunned Press Room...

performance, the nozzle should be ambient at sea-level; however, if a rocket engine is primarily designed for use at high altitudes and is only providing additional thrust to another "first stage" engine during liftoff in a multi-stage design, then designers will usually opt for an overexpanded (at sea-level) design. This is the technique employed on the Space shuttle

Space Shuttle

The Space Shuttle was a manned orbital rocket and spacecraft system operated by NASA on 135 missions from 1981 to 2011. The system combined rocket launch, orbital spacecraft, and re-entry spaceplane with modular add-ons...

's main engines, which spend most of their powered trajectory in near-vacuum while the shuttle's two Solid Rocket Booster

Solid rocket booster

Solid rocket boosters or Solid Rocket Motors, SRM, are used to provide thrust in spacecraft launches from the launchpad up to burnout of the SRBs. Many launch vehicles include SRBs, including the Ariane 5, Atlas V , and the NASA Space Shuttle...

s provide the majority of the liftoff thrust.

Vacuum use

For nozzles that are used in vacuum or at very high altitude, it is impossible to match ambient pressure; rather, larger area ratio nozzles are usually more efficient. However, a very long nozzle has significant mass, a drawback in and of itself. A length that optimises overall vehicle performance typically has to be found. Additionally, as the temperature of the gas in the nozzle decreases some components of the exhaust gases (such as water vapour from the combustion process) may condense, or even freeze. This is highly undesirable and needs to be avoided.Magnetic nozzles have been proposed for some types of propulsion (for example VASIMR), in which the flow of plasma

Plasma (physics)

In physics and chemistry, plasma is a state of matter similar to gas in which a certain portion of the particles are ionized. Heating a gas may ionize its molecules or atoms , thus turning it into a plasma, which contains charged particles: positive ions and negative electrons or ions...

or ions are directed by magnetic field

Magnetic field

A magnetic field is a mathematical description of the magnetic influence of electric currents and magnetic materials. The magnetic field at any given point is specified by both a direction and a magnitude ; as such it is a vector field.Technically, a magnetic field is a pseudo vector;...

s instead of walls made of solid materials. These can be advantageous since a magnetic field itself cannot melt and the plasma temperatures can reach millions of kelvin

Kelvin

The kelvin is a unit of measurement for temperature. It is one of the seven base units in the International System of Units and is assigned the unit symbol K. The Kelvin scale is an absolute, thermodynamic temperature scale using as its null point absolute zero, the temperature at which all...

s. However, there are often thermal design challenges presented by the coils themselves, particularly if superconducting coils are used to form the throat and expansion fields.

1-D Analysis of gas flow in rocket engine nozzles

The analysis of gas flow through de Laval nozzles involves a number of concepts and assumptions:

- For simplicity, the combustion gas is assumed to be an ideal gasIdeal gasAn ideal gas is a theoretical gas composed of a set of randomly-moving, non-interacting point particles. The ideal gas concept is useful because it obeys the ideal gas law, a simplified equation of state, and is amenable to analysis under statistical mechanics.At normal conditions such as...

. - The gas flow is isentropic (i.e., at constant entropyEntropyEntropy is a thermodynamic property that can be used to determine the energy available for useful work in a thermodynamic process, such as in energy conversion devices, engines, or machines. Such devices can only be driven by convertible energy, and have a theoretical maximum efficiency when...

), frictionless, and adiabaticAdiabatic processIn thermodynamics, an adiabatic process or an isocaloric process is a thermodynamic process in which the net heat transfer to or from the working fluid is zero. Such a process can occur if the container of the system has thermally-insulated walls or the process happens in an extremely short time,...

(i.e., there is little or no heat gained or lost) - The gas flow is constant (i.e., steady) during the period of the propellantPropellantA propellant is a material that produces pressurized gas that:* can be directed through a nozzle, thereby producing thrust ;...

burn. - The gas flow is along a straight line from gas inlet to exhaust gas exit (i.e., along the nozzle's axis of symmetry)

- The gas flow behavior is compressibleCompressible flowCompressible flow is the area of fluid mechanics that deals with fluids in which the fluid density varies significantly in response to a change in pressure. Compressibility effects are typically considered significant if the Mach number of the flow exceeds 0.3, or if the fluid undergoes very large...

since the flow is at very high velocities.

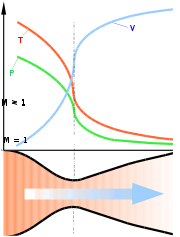

As the combustion gas enters the rocket nozzle, it is traveling at subsonic

Speed of sound

The speed of sound is the distance travelled during a unit of time by a sound wave propagating through an elastic medium. In dry air at , the speed of sound is . This is , or about one kilometer in three seconds or approximately one mile in five seconds....

velocities. As the throat contracts down the gas is forced to accelerate until at the nozzle throat, where the cross-sectional area is the smallest, the linear velocity becomes sonic

Mach number

Mach number is the speed of an object moving through air, or any other fluid substance, divided by the speed of sound as it is in that substance for its particular physical conditions, including those of temperature and pressure...

. From the throat the cross-sectional area then increases, the gas expands and the linear velocity becomes progressively more supersonic

Supersonic

Supersonic speed is a rate of travel of an object that exceeds the speed of sound . For objects traveling in dry air of a temperature of 20 °C this speed is approximately 343 m/s, 1,125 ft/s, 768 mph or 1,235 km/h. Speeds greater than five times the speed of sound are often...

.

The linear velocity of the exiting exhaust gases can be calculated using the following equation

| where: | |

|

= Exhaust velocity at nozzle exit, m/s |

|---|---|

|

= absolute temperature Temperature Temperature is a physical property of matter that quantitatively expresses the common notions of hot and cold. Objects of low temperature are cold, while various degrees of higher temperatures are referred to as warm or hot... of inlet gas, K |

|

= Universal gas law constant Gas constant The gas constant is a physical constant which is featured in many fundamental equations in the physical sciences, such as the ideal gas law and the Nernst equation. It is equivalent to the Boltzmann constant, but expressed in units of energy The gas constant (also known as the molar, universal,... = 8314.5 J/(kmol·K) |

|

= the gas molecular mass Molecular mass The molecular mass of a substance is the mass of one molecule of that substance, in unified atomic mass unit u... , kg/kmol (also known as the molecular weight) |

|

=  = isentropic expansion factor = isentropic expansion factor |

|

= specific heat of the gas at constant pressure |

|

= specific heat of the gas at constant volume |

|

= absolute pressure Pressure Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :... of exhaust gas at nozzle exit, Pa Pascal (unit) The pascal is the SI derived unit of pressure, internal pressure, stress, Young's modulus and tensile strength, named after the French mathematician, physicist, inventor, writer, and philosopher Blaise Pascal. It is a measure of force per unit area, defined as one newton per square metre... |

|

= absolute pressure of inlet gas, Pa |

Some typical values of the exhaust gas velocity Ve for rocket engines burning various propellants are:

- 1.7 to 2.9 km/s (3800 to 6500 mi/h) for liquid monopropellantMonopropellantMonopropellants are propellants composed of chemicals or mixtures of chemicals which can be stored in a single container with some degree of safety. While stable under defined storage conditions, they react very rapidly under certain other conditions to produce a large volume of energetic gases...

s - 2.9 to 4.5 km/s (6500 to 10100 mi/h) for liquid bipropellants

- 2.1 to 3.2 km/s (4700 to 7200 mi/h) for solid propellantSolid rocketA solid rocket or a solid-fuel rocket is a rocket engine that uses solid propellants . The earliest rockets were solid-fuel rockets powered by gunpowder; they were used by the Chinese in warfare as early as the 13th century and later by the Mongols, Arabs, and Indians.All rockets used some form of...

s

As a note of interest, Ve is sometimes referred to as the ideal exhaust gas velocity because it based on the assumption that the exhaust gas behaves as an ideal gas.

As an example calculation using the above equation, assume that the propellant combustion gases are: at an absolute pressure entering the nozzle of P = 7.0 MPa and exit the rocket exhaust at an absolute pressure of Pe = 0.1 MPa; at an absolute temperature of T = 3500 K; with an isentropic expansion factor of k = 1.22 and a molar mass of M = 22 kg/kmol. Using those values in the above equation yields an exhaust velocity Ve = 2802 m/s or 2.80 km/s which is consistent with above typical values.

The technical literature can be very confusing because many authors fail to explain whether they are using the universal gas law constant R which applies to any ideal gas

Ideal gas

An ideal gas is a theoretical gas composed of a set of randomly-moving, non-interacting point particles. The ideal gas concept is useful because it obeys the ideal gas law, a simplified equation of state, and is amenable to analysis under statistical mechanics.At normal conditions such as...

or whether they are using the gas law constant Rs which only applies to a specific individual gas. The relationship between the two constants is Rs = R/M.

Specific Impulse

ThrustThrust

Thrust is a reaction force described quantitatively by Newton's second and third laws. When a system expels or accelerates mass in one direction the accelerated mass will cause a force of equal magnitude but opposite direction on that system....

is the force which moves a rocket through the air, and through space. Thrust is generated by the propulsion

Spacecraft propulsion

Spacecraft propulsion is any method used to accelerate spacecraft and artificial satellites. There are many different methods. Each method has drawbacks and advantages, and spacecraft propulsion is an active area of research. However, most spacecraft today are propelled by forcing a gas from the...

system of the rocket through the application of Newton's third law of motion: "For every action there is an equal and opposite reaction". A gas or working fluid is accelerated out the rear of the rocket engine nozzle and the rocket is accelerated in the opposite direction. The thrust of a rocket engine nozzle can be defined as:

|

|

|---|---|

|

|

and for perfectly expanded nozzles, this reduces to:

|

|

|---|

The specific impulse,

, is the ratio of the amount of thrust produced to the weight flow of the propellant

, is the ratio of the amount of thrust produced to the weight flow of the propellantPropellant

A propellant is a material that produces pressurized gas that:* can be directed through a nozzle, thereby producing thrust ;...

s. It is a measure of the fuel efficiency of a rocket engine. It can be obtained from:

| where: | |

|

= gross rocket engine thrust, N |

|---|---|

|

= mass flow rate of exhaust gas, kg/s |

|

= exhaust gas velocity at nozzle exit, m/s |

|

= exhaust gas pressure at nozzle exit, Pa |

|

= external ambient pressure, Pa (also known as free stream pressure) |

|

= cross-sectional area of nozzle exhaust exit, m² |

|

= equivalent (or effective) exhaust gas velocity at nozzle exit, m/s |

|

= specific impulse, s |

|

= Gravitational acceleration at sea level on Earth = 9.807 m/s² |

In certain cases, where

equals

equals  , then:

, then:

In cases where this may not be the case since for a rocket nozzle

is proportional to

is proportional to  , then it is possible to define a constant quantity which is the vacuum

, then it is possible to define a constant quantity which is the vacuum  for any given engine thus:

for any given engine thus:

and hence:

which is simply the vacuum thrust minus the force of the ambient atmospheric pressure acting over the exit plane.

Essentially then, for rocket nozzles, the ambient pressure acting over the engine largely cancels but effectively acts over the exit plane of the rocket engine in a rearward direction, while the exhaust jet generates forward thrust.

Aerostatic back-pressure and optimum expansion

As the gas travels down the expansion part of the nozzle the pressure and temperature decreases and the speed of the gas increases.The supersonic nature of the exhaust jet means that the pressure of the exhaust can be significantly different from ambient pressure- the outside air is unable to equalize the pressure upstream due to the very high jet velocity. Therefore, for supersonic nozzles, it is actually possible for the pressure of the gas exiting the nozzle to go significantly below or very greatly above ambient pressure.

If the exit pressure is too low, then the jet can separate from the nozzle. This is often unstable and the jet will generally cause large off-axis thrusts, and may mechanically damage the nozzle.

This separation generally occurs if the exit pressure goes below roughly 30-45% of ambient, but may be delayed to far lower pressures if the nozzle is designed to increase the pressure at the rim, as is achieved with the SSME

Space Shuttle main engine

The RS-25, otherwise known as the Space Shuttle Main Engine , is a reusable liquid-fuel rocket engine built by Pratt & Whitney Rocketdyne for the Space Shuttle, running on liquid hydrogen and oxygen. Each Space Shuttle was propelled by three SSMEs mated to one powerhead...

(1-2 psi at 15 psi ambient)..

These are generally very similar to bell nozzles but include an insert or mechanism by which the exit area ratio can be increased as ambient pressure is reduced.

Dual-mode nozzles include:

- the dual-expander nozzle and

- the dual-throat nozzle.

These have either two throats or two thrust chambers (with corresponding throats). The central throat is of a standard design and is surrounded by an annular throat which exhausts gases from the same (dual-throat) or a separate (dual-expander) thrust chamber. Both throats would, in either case, discharge into a bell nozzle. At higher altitues where the ambient pressure is lower, the central nozzle would be shut off reducing the throat area and thereby increasing the nozzle area ratio. These designs require additional complexity but an advantage of having two thrust chambers is that they can be configured to burn different propellants or different fuel mixture ratios. Similarly, Aerojet has also designed a nozzle called the 'Thrust Augmented Nozzle' which injects propellant and oxidiser directly into the nozzle section for combustion allowing larger area ratio nozzles to be used deeper in an atmosphere than they would without augmentation due to effects of flow separation. They would again allow multiple propellants to be used (such as RP-1) further increasing thrust.

There is also a SERN

SERN

A SERN, which stands for single expansion ramp nozzle, is a type of linear expansion nozzle where the gas pressure transfers work only on one side. Traditional nozzles are axially symmetric, and therefore surround the expanding gas. Linear nozzles are not axially symmetric, but consist of a 2D...

(Single Expansion Ramp Nozzle), a linear expansion nozzle where the gas pressure transfers work only on one side and which could be described as a single-sided aerospike nozzle.

See also

- Choked flowChoked flowChoked flow is a compressible flow effect. The parameter that becomes "choked" or "limited" is the velocity or the mass flow rate.Choked flow is a fluid dynamic condition associated with the Venturi effect...

- when the gas speeds reaches the speed of sound in the gas - de Laval nozzleDe Laval nozzleA de Laval nozzle is a tube that is pinched in the middle, making a carefully balanced, asymmetric hourglass-shape...

- a convergent-divergent nozzle designed to give supersonic speeds - Dual-thrustDual-thrustIn a dual-thrust solid fuel rocket motor, the propellant mass is composed of two different types or densities of fuel. In the case of a tandem dual-thrust motor, the fuel closest to the rocket nozzle burns fast and the fuel further into the motor's body burns slower...

rocket motors - Jet engineJet engineA jet engine is a reaction engine that discharges a fast moving jet to generate thrust by jet propulsion and in accordance with Newton's laws of motion. This broad definition of jet engines includes turbojets, turbofans, rockets, ramjets, pulse jets...

- engines propelled by jets (including rockets) - Multistage rocketMultistage rocketA multistage rocket is a rocket that usestwo or more stages, each of which contains its own engines and propellant. A tandem or serial stage is mounted on top of another stage; a parallel stage is attached alongside another stage. The result is effectively two or more rockets stacked on top of or...

- NK-33NK-33The NK-33 and NK-43 are rocket engines designed and built in the late 1960s and early 1970s by the Kuznetsov Design Bureau. They were intended for the ill-fated Soviet N-1 rocket moon shot. The NK-33 engine achieves the highest thrust-to-weight ratio of any Earth-launchable rocket engine, whilst...

- Russian rocket engine - Pulse jet enginePulse jet engineA pulse jet engine is a type of jet engine in which combustion occurs in pulses. Pulsejet engines can be made with few or no moving parts, and are capable of running statically....

- Pulsed rocket motor

- Reaction Engines Skylon - a single-stage-to-orbit spaceplane powered by hybrid air-breathing/internal oxygen engine (Reaction Engines SABRE)

- RocketRocketA rocket is a missile, spacecraft, aircraft or other vehicle which obtains thrust from a rocket engine. In all rockets, the exhaust is formed entirely from propellants carried within the rocket before use. Rocket engines work by action and reaction...

- rocket vehicles - Rocket engines - used to propel rocket vehicles

- Rocket Propulsion Analysis

- SERN, Single-expansion ramp nozzleSERNA SERN, which stands for single expansion ramp nozzle, is a type of linear expansion nozzle where the gas pressure transfers work only on one side. Traditional nozzles are axially symmetric, and therefore surround the expanding gas. Linear nozzles are not axially symmetric, but consist of a 2D...

- a non-axisymmetric aerospike - Shock diamondShock diamondShock diamonds are a formation of stationary wave patterns that appears in the supersonic exhaust plume of an aerospace propulsion system, such as a supersonic jet engine, rocket, ramjet, or scramjet, when it is operated in an atmosphere...

s - these visible bands form in the exhaust of rocket engines - Solid-fuel rocket

- Spacecraft propulsionSpacecraft propulsionSpacecraft propulsion is any method used to accelerate spacecraft and artificial satellites. There are many different methods. Each method has drawbacks and advantages, and spacecraft propulsion is an active area of research. However, most spacecraft today are propelled by forcing a gas from the...

- Specific impulseSpecific impulseSpecific impulse is a way to describe the efficiency of rocket and jet engines. It represents the derivative of the impulse with respect to amount of propellant used, i.e., the thrust divided by the amount of propellant used per unit time. If the "amount" of propellant is given in terms of mass ,...

- a measure of exhaust speed - Staged combustion cycle (rocket)Staged combustion cycle (rocket)The staged combustion cycle, also called topping cycle or pre-burner cycle, is a thermodynamic cycle of bipropellant rocket engines. Some of the propellant is burned in a pre-burner and the resulting hot gas is used to power the engine's turbines and pumps...

- a type of rocket engine

External links

- Amateur and Experimental Rocketry

- NASA web site

- NASA Space Vehicle Design Criteria, Liquid Rocket Engine Nozzles

- NASA's "Beginners' Guide to Rockets"

- The Aerospike Engine

- Richard Nakka's Experimental Rocketry Web Site

- "Rocket Propulsion" on Robert Braeuning's Web Site

- Free Design Tool for Liquid Rocket Engine Thermodynamic Analysis